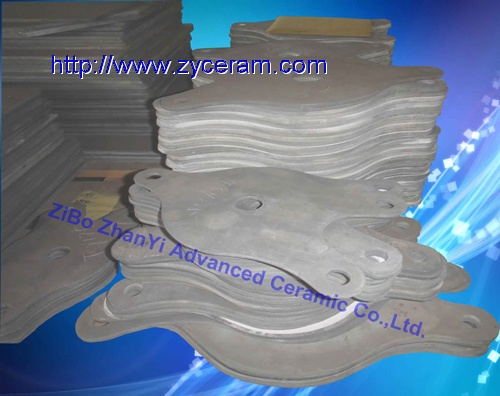

Antioxidative NSiC Batts Using In Furnaces

Fine Si3N4 bonded SiC batts is a sort of structure ceramic material, NSiC product is shaped by casting with the composition of high pure SiC and Si powder, and sintered through nitrified reaction.

NSiC batts has higher strength than RSiC and has excellent oxidation resistance. Maximum working temperature is 1500deg.In addition to its structural properties, NSiC batts has excellent wear properties and is resistant to corrosion and erosion by molten metals. So that it can be used in direct contact with molten aluminum, zinc, copper, magnesium. NSiC has been successfully used for protection tubes for temperature measurement.

NSiC batts offer many engineering property levels that are not found in other refractory materials, such as high strength at using temperature, excellent load bearing strength and resistance to chemical and abrasive attack.

Characteristic Of NSiC Batts:

1. Excellent oxidation resistance

2. Good wear resistance

3. Excellent corrosion resistance

4. High temperature flexural performance

5. Excellent load bearing strength

The Data Sheet Of The Silicon Nitride Bond Silicon Carbide Batts

Bulk Density: 2.75-2.82g/cm3

Porosity: 10-12%

Compression Strength: 600-700Mpa

Bending Strength: 160-180Mpa

Young’s Modulus: 220-260Gpa

Thermal Conductivity: 15W/MK

Thermal Expansion α(20-1000℃): 5.0x10-6k-1

Max. Working Temperature: 1500℃

Si3N4: 20-40%

SiC: 60-80%

Silicon Nitride bond silicon carbide batts are widely used in tablewar ceramics industry.

NSiC batts has higher strength than RSiC and has excellent oxidation resistance. Maximum working temperature is 1500deg.In addition to its structural properties, NSiC batts has excellent wear properties and is resistant to corrosion and erosion by molten metals. So that it can be used in direct contact with molten aluminum, zinc, copper, magnesium. NSiC has been successfully used for protection tubes for temperature measurement.

NSiC batts offer many engineering property levels that are not found in other refractory materials, such as high strength at using temperature, excellent load bearing strength and resistance to chemical and abrasive attack.

Characteristic Of NSiC Batts:

1. Excellent oxidation resistance

2. Good wear resistance

3. Excellent corrosion resistance

4. High temperature flexural performance

5. Excellent load bearing strength

The Data Sheet Of The Silicon Nitride Bond Silicon Carbide Batts

Bulk Density: 2.75-2.82g/cm3

Porosity: 10-12%

Compression Strength: 600-700Mpa

Bending Strength: 160-180Mpa

Young’s Modulus: 220-260Gpa

Thermal Conductivity: 15W/MK

Thermal Expansion α(20-1000℃): 5.0x10-6k-1

Max. Working Temperature: 1500℃

Si3N4: 20-40%

SiC: 60-80%

Silicon Nitride bond silicon carbide batts are widely used in tablewar ceramics industry.